Concrete flooring is a staple in construction due to its strength and versatility. But what if you could enhance its performance even further? That’s where PP (Polypropylene) fiber comes into play. At Indus Arabia, we’re excited to share how integrating PP fiber into your concrete flooring mix can revolutionize your project, providing a host of benefits from increased durability to cost savings.

What is PP Fiber?

Definition and Composition

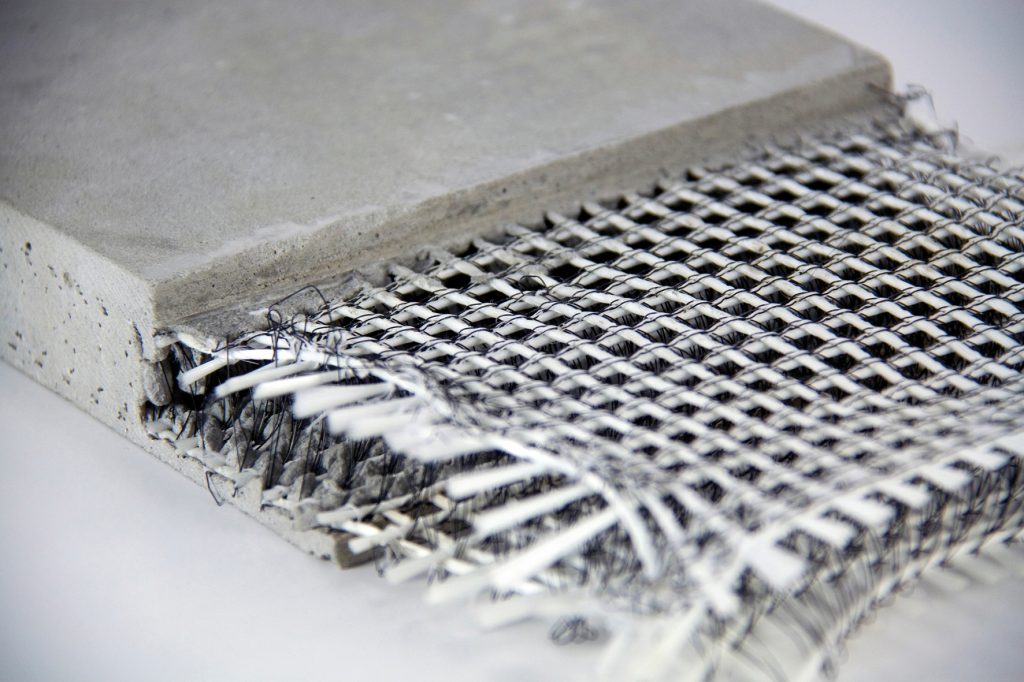

PP fiber, short for polypropylene fiber, is a synthetic fiber known for its impressive strength and flexibility. Made from polypropylene, a type of plastic, this fiber is added to concrete to enhance its performance. Its key characteristics include:

- Strength: PP fibers are tough and resilient, capable of reinforcing concrete against stress.

- Flexibility: Unlike some other reinforcement materials, PP fibers offer flexibility, which helps in controlling cracking.

- Chemical Resistance: They resist chemical attacks, making them ideal for various environments.

How It’s Used in Concrete

Incorporating PP fiber into concrete is straightforward. During the mixing process, the fibers are evenly distributed throughout the concrete mix. This helps to integrate the fibers into the concrete matrix, enhancing the material’s overall properties.

The result is a concrete floor that’s not just stronger but also more resistant to common issues like cracking and abrasion.

Benefits of Using PP Fiber in Concrete Flooring

Increased Crack Resistance

One of the standout advantages of PP fiber is its ability to reduce and control cracking. Concrete is prone to cracking due to various factors, including shrinkage and temperature changes. PP fiber helps mitigate this by reinforcing the concrete, making it more resistant to these stresses.

Compared to traditional reinforcement methods like rebar, PP fiber offers a more uniform distribution of reinforcement, which can significantly reduce the incidence of cracks and extend the life of the flooring.

Improved Impact and Abrasion Resistance

Concrete floors are often subjected to heavy impacts and abrasion, especially in industrial settings. PP fiber enhances the concrete’s resistance to these stresses, making it more durable and less likely to suffer damage from heavy machinery, foot traffic, or other harsh conditions.

This improved impact and abrasion resistance can save on maintenance and repair costs over time, making PP fiber a cost-effective solution in the long run.

Enhanced Flexibility and Strength

In addition to crack resistance, PP fiber also boosts the tensile strength and flexibility of concrete. This means that your flooring will be more able to handle various types of stress without failing, providing a more reliable surface for any application.

The added flexibility also allows the concrete to handle minor movements and shifts without developing cracks, further enhancing its longevity.

Cost Efficiency

Investing in PP fiber might seem like an additional expense, but it’s actually a cost-effective choice in the long run. By reducing the need for repairs and extending the lifespan of the concrete, PP fiber helps to lower maintenance costs. Its durability and reduced likelihood of cracking translate into savings over time, making it a smart investment for any concrete flooring project.

Application Process of PP Fiber in Concrete Flooring

Mixing and Preparation

To get the best results from PP fiber, proper mixing is crucial. The fibers are added to the concrete mix during the batching process. It’s important to ensure an even distribution of fibers throughout the mix to achieve the desired reinforcement.

The amount of PP fiber needed depends on the specific requirements of the project, including the expected load and environmental conditions. Our experts at Indus Arabia can help determine the right mix for your needs.

Application Techniques

Once the concrete mix with PP fiber is prepared, it’s poured and finished just like regular concrete. The key is to ensure that the fiber is well distributed throughout the mix, which can be achieved through proper mixing techniques and application methods.

Finishing the surface of the concrete is essential to achieving a smooth and durable finish. Techniques like troweling and smoothing help ensure that the fiber is effectively integrated and that the surface is ready for use.

Curing and Maintenance

Proper curing is vital to maximize the benefits of PP fiber. Curing involves maintaining adequate moisture and temperature conditions to allow the concrete to set and develop its full strength. This step is crucial for achieving the best performance from the PP fiber reinforcement.

Regular maintenance is also important to keep your concrete flooring in top condition. While PP fiber enhances durability, proper care and maintenance will ensure that your flooring continues to perform well over time.

Applications in Various Settings

Industrial Floors

In industrial environments, concrete floors face extreme conditions, including heavy machinery and constant traffic. PP fiber’s enhanced crack resistance and impact resistance make it an ideal choice for these settings. It ensures that your floors remain durable and functional even under harsh conditions.

Commercial and Retail Spaces

For commercial and retail spaces, the benefits of PP fiber extend beyond durability. It also helps in maintaining a visually appealing floor by reducing the likelihood of cracks and damage. This can enhance the overall aesthetic of your space, making it look well-maintained and professional.

Residential Projects

Even in residential settings, PP fiber can offer significant advantages. Whether you’re working on a garage floor, patio, or even a high-end interior floor, PP fiber enhances the durability and longevity of the concrete. It helps in creating a floor that not only looks great but also stands up to everyday wear and tear.

Why Choose Indus Arabia for Your PP Fiber Solutions?

Expertise and Experience

At Indus Arabia, we pride ourselves on our expertise in advanced concrete solutions. Our team is experienced in working with PP fiber and can provide tailored recommendations based on your specific project needs.

Customized Solutions

We understand that every project is unique, and we offer customized PP fiber solutions to meet your requirements. Whether you’re working on a large industrial floor or a small residential project, we can design a solution that fits your needs.

Quality Assurance

Quality is at the heart of everything we do. From selecting the best materials to applying them with precision, we ensure that every project meets our high standards. When you choose Indus Arabia, you’re choosing a partner committed to delivering top-notch results.

Contact Indus Arabia for Your PP Fiber Solutions

Ready to enhance your concrete flooring with PP fiber? Indus Arabia is here to help. Our team of experts is ready to assist you with all your concrete needs, from mixing and application to maintenance and quality assurance.

- Location: Al-khobar, Saudi Arabia

- Phone: (+966)570791955

- Email: info@indusarabia.com.sa

- Website: www.indusarabia.com.sa

Get in touch with us today to learn more about how PP fiber can benefit your concrete flooring project. We look forward to helping you achieve durable, cost-effective, and beautiful concrete surfaces.

Conclusion

Incorporating PP fiber into your concrete flooring mix is a smart choice for enhancing durability, reducing cracks, and improving overall performance. With the expertise and customized solutions offered by Indus Arabia, you can achieve floors that stand the test of time. Contact us today to explore how PP fiber can transform your concrete flooring projects into long-lasting, high-quality surfaces.