Crack Control in Concrete: Understanding the Causes and Solutions

Cracks in concrete are a common issue that can affect the structural integrity and aesthetic appeal of construction projects. While minor cracks may not immediately indicate severe problems, they can lead to significant issues if not properly addressed. Understanding the causes of cracks and the available solutions, including the use of steel fibers and other types of fibers, is crucial for ensuring the durability and longevity of concrete structures.

Causes of Cracks in Concrete

Several factors contribute to the formation of cracks in concrete, including:

- Shrinkage: As concrete dries and hardens, it undergoes shrinkage due to the evaporation of water. This shrinkage can lead to tensile stresses, which, if not properly managed, can result in cracks.

- Thermal Expansion and Contraction: Concrete expands when heated and contracts when cooled. Significant temperature fluctuations can cause thermal stresses, leading to cracks.

- Load-Bearing Stress: Overloading or uneven distribution of loads can cause concrete to crack. This is especially common in structures like bridges, buildings, and pavements.

- Improper Curing: Inadequate curing can result in rapid drying of concrete, leading to surface cracks. Proper curing is essential to allow the concrete to gain strength and resist cracking.

- Structural Movements: Settling of the foundation, seismic activity, or other movements in the structure can cause cracks to form in concrete.

Solutions for Crack Control

To mitigate and control cracks in concrete, various methods and materials are employed. These solutions aim to enhance the concrete’s tensile strength, reduce shrinkage, and improve its overall performance.

- Proper Mix Design: Ensuring an optimal water-cement ratio, using appropriate aggregates, and incorporating admixtures can significantly reduce the risk of cracking.

- Controlled Curing: Implementing proper curing techniques, such as keeping the concrete surface moist and using curing compounds, helps prevent premature drying and shrinkage cracks.

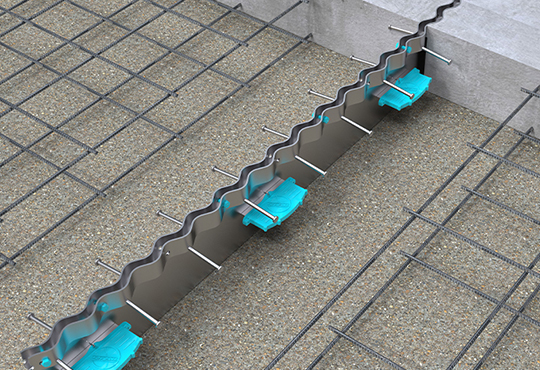

- Reinforcement: Traditional reinforcement methods, such as using steel bars (rebar), help absorb tensile stresses and distribute them across a larger area, reducing the likelihood of cracks.

- Use of Fibers: Incorporating fibers into the concrete mix is an effective way to control cracking. Fibers enhance the tensile strength of concrete and reduce the width and propagation of cracks. Various types of fibers are used in concrete, including:

- Steel Fibers: Steel fibers are commonly used in concrete to improve its resistance to cracking. These fibers distribute the tensile stresses more evenly, reducing the occurrence of large cracks. Steel fibers are especially beneficial in industrial floors, pavements, and precast elements.

- Polypropylene Fibers: These synthetic fibers are added to concrete to reduce plastic shrinkage and improve durability. Polypropylene fibers are lightweight, non-corrosive, and effective in controlling micro-cracks.

- Glass Fibers: Glass fibers enhance the concrete’s resistance to cracking caused by environmental factors, such as temperature changes and moisture. They are often used in decorative concrete applications.

- Basalt Fibers: Derived from volcanic rocks, basalt fibers provide excellent thermal stability and resistance to chemical attacks. They are suitable for use in high-temperature environments.

- Carbon Fibers: Carbon fibers offer high strength and stiffness, making them ideal for applications where structural reinforcement is critical. They are often used in specialized projects, such as bridges and high-rise buildings.

Conclusion

Crack control in concrete is a vital aspect of ensuring the structural integrity and durability of construction projects. Understanding the causes of cracks and implementing appropriate solutions, such as using steel fibers and other types of fibers, can significantly reduce the risk of cracking. By employing the right mix design, curing techniques, and reinforcement methods, construction professionals can enhance the performance and lifespan of concrete structures, ultimately leading to safer and more resilient buildings and infrastructure.