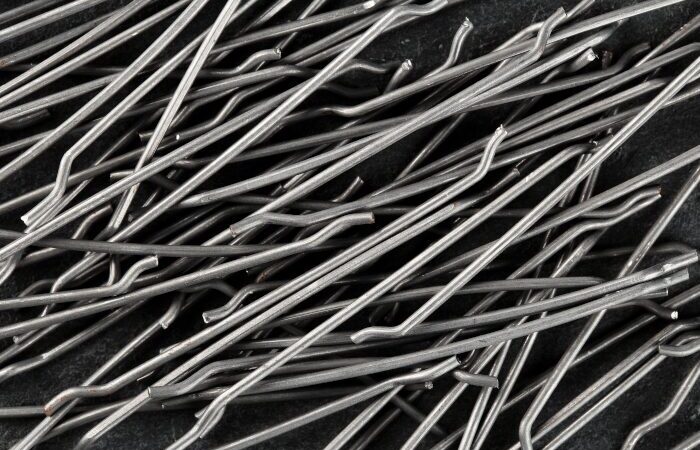

What Are Polypropylene (PP) Fibers?

Polypropylene fibers, commonly known as PP fibers, are synthetic fibers used in concrete to improve its strength, durability, and resistance to cracking. These fibers are mixed into the concrete during the batching process, where they distribute evenly throughout the mixture. Indus Arabia offers high-performance polypropylene fibers designed to meet the specific needs of commercial and industrial projects in Saudi Arabia, providing an advanced solution for reinforced concrete.

The Role of Polypropylene Fibers in Concrete Reinforcement

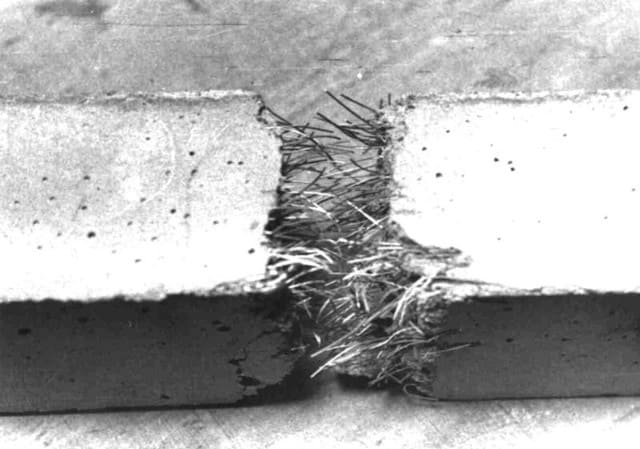

Enhanced Crack Resistance

One of the primary benefits of adding polypropylene fibers to concrete is their ability to improve crack resistance. These fibers help control the formation of micro-cracks during the curing process by providing a three-dimensional reinforcement throughout the concrete. This reduces the likelihood of cracks developing and helps maintain the structural integrity of the concrete.

- Crack Prevention: Polypropylene fibers help reduce the occurrence of micro-cracks, ensuring a more durable and long-lasting concrete surface.

Improved Durability

Polypropylene fibers enhance the overall durability of concrete by providing additional tensile strength and impact resistance. This makes the concrete more resilient to heavy loads, abrasion, and environmental factors, extending the life of the concrete structure.

- Increased Strength: By adding tensile strength to the concrete, PP fibers improve its ability to withstand heavy use and harsh conditions.

Shrinkage Control

During the curing process, concrete tends to shrink, which can lead to cracking. Polypropylene fibers help control shrinkage by reducing the amount of water required in the concrete mix. This minimizes the shrinkage potential and reduces the risk of cracking, leading to a more stable and durable concrete structure.

- Shrinkage Reduction: Polypropylene fibers help control shrinkage, minimizing the risk of cracking during the curing process.

Applications of Polypropylene Fibers

Industrial Floors

In industrial settings, concrete floors are subjected to heavy loads, machinery, and frequent traffic. Polypropylene fibers reinforce the concrete, making it more resistant to wear and damage, ensuring that the floors can handle the demands of an industrial environment.

- Heavy-Duty Flooring: PP fibers enhance the durability and performance of industrial floors, making them suitable for demanding applications.

Commercial Spaces

For commercial spaces, such as shopping malls, office buildings, and retail stores, the appearance and longevity of the floors are important. Polypropylene fibers help create a smooth, crack-resistant surface that can withstand heavy foot traffic and maintain its appearance over time.

- Aesthetic and Durable: PP fibers ensure that commercial floors remain crack-free and visually appealing, even with heavy use.

Precast Concrete

Polypropylene fibers are also widely used in precast concrete products, such as panels, pipes, and barriers. These fibers improve the strength and durability of the precast elements, making them more resistant to cracking and damage during transportation and installation.

- Precast Reinforcement: Enhance the quality and durability of precast concrete products with the addition of PP fibers.

Benefits of Using Indus Arabia’s Polypropylene Fibers

Long-Lasting Performance

Indus Arabia’s polypropylene fibers are engineered to provide long-lasting performance, ensuring that your concrete structures remain strong and durable for years to come. These fibers are designed to withstand the rigors of industrial and commercial environments, reducing the need for repairs and maintenance.

- Durable Solution: Our PP fibers enhance the lifespan of concrete, reducing the need for costly repairs and maintenance.

Cost-Effective Reinforcement

Investing in polypropylene fibers is a cost-effective way to reinforce concrete without the need for traditional steel reinforcement. These fibers provide an affordable solution for improving the strength and durability of concrete, making them a valuable addition to any construction project.

- Affordable Reinforcement: PP fibers offer a cost-effective alternative to traditional reinforcement methods, providing excellent value for your investment.

Easy to Use

Polypropylene fibers are easy to use and can be added directly to the concrete mix during the batching process. This simplifies the construction process and ensures that the fibers are evenly distributed throughout the concrete, providing consistent reinforcement.

- Simple Application: PP fibers are easy to incorporate into your concrete mix, ensuring consistent and reliable results.

How to Use Polypropylene Fibers in Concrete

Mixing Process

Polypropylene fibers should be added to the concrete mix during the batching process. They are typically added at a rate of 0.1% to 0.3% by volume, depending on the desired level of reinforcement. The fibers should be mixed thoroughly to ensure even distribution throughout the concrete.

- Thorough Mixing: Proper mixing ensures that the PP fibers are evenly distributed, providing uniform reinforcement throughout the concrete.

Compatibility with Other Admixtures

Polypropylene fibers are compatible with most common concrete admixtures, including water reducers, accelerators, and retarders. This allows for flexibility in the concrete mix design, ensuring that the fibers can be used alongside other admixtures to achieve the desired performance characteristics.

- Flexible Integration: PP fibers can be used in conjunction with other admixtures to optimize the performance of your concrete mix.

Why Choose Indus Arabia for Polypropylene Fibers?

Expertise in Concrete Solutions

With years of experience in the concrete industry, Indus Arabia is a trusted provider of high-quality polypropylene fibers in Saudi Arabia. Our team of experts is dedicated to delivering products that meet the highest standards of quality and performance, ensuring that your projects are successful.

- Trusted Expertise: Rely on our knowledge and experience to provide polypropylene fibers that meet the demands of your concrete projects.

Commitment to Quality

At Indus Arabia, quality is our top priority. Our polypropylene fibers are made from high-grade materials and are rigorously tested to ensure that they meet the specific needs of our clients. We are committed to providing products that deliver superior performance and reliability.

- Top-Quality Products: Our commitment to quality ensures that you receive the best polypropylene fibers available in the market.

Comprehensive Support

From the initial consultation to the final application, Indus Arabia provides comprehensive support throughout your project. Our team works closely with you to understand your needs and deliver a solution that meets your exact specifications.

- Full-Service Support: We are with you every step of the way, ensuring that your project is a success.

Conclusion

Polypropylene fibers are a versatile and effective solution for reinforcing concrete in industrial, commercial, and precast applications. At Indus Arabia, we offer high-performance PP fibers that enhance the strength, durability, and crack resistance of concrete floors and structures. Whether you’re looking to improve the performance of industrial floors, commercial spaces, or precast products, our polypropylene fibers provide the ideal solution.

Contact Us Today

Ready to reinforce your concrete with our premium polypropylene fibers? Contact Indus Arabia today to learn more about our products and services. Contact Us for more information and to request a consultation.