Quality Control at Indus Arabia

The International Surface Regularity Standards

At Indus Arabia, we adhere to the most accepted and widely implemented international surface regularity specifications to ensure our floors meet the highest standards. These specifications include:

At Indus Arabia, we adhere to the most accepted and widely implemented international surface regularity specifications to ensure our floors meet the highest standards. These specifications include:

- Great Britain: Concrete Society’s TR34 Table 3.1 (FM) and Table 3.2 (DM)

- Germany: DIN 18202 Table 3 Groups 3 & 4, DIN 15185 Tables 1 & 2

- USA: ASTM E 1155 M – F numbers, F min numbers

Flatness and Levelness Requirements

To define floor flatness requirements, floors are divided into Free Movement Areas (FM) and Defined Movement Areas (DM).

Free Movement (FM) Areas

In FM areas, materials handling equipment (MHE) can move freely or randomly in any direction. These areas typically include marshalling zones, block stacking areas, and aisles wider than 2.8 meters.

Defined Movement (DM) Areas

DM areas have fixed paths for MHE, usually found in high-level storage racking with very narrow aisles (VNAs).

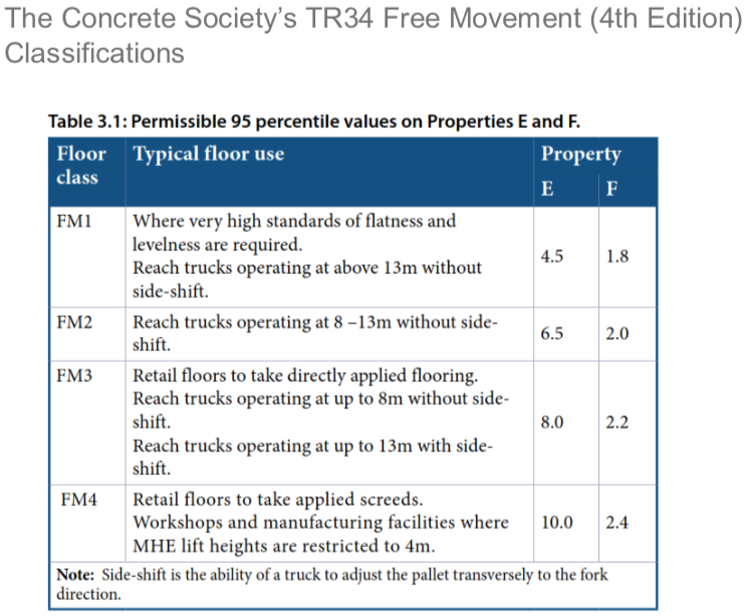

Free Movement Floors (TR34 Edition 4th 2013 Table 3.1)

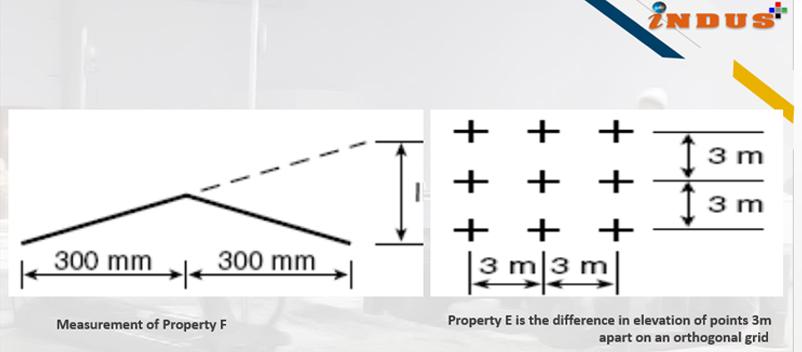

TR34 specifications are the most comprehensive method for specifying the surface regularity of free movement floors. They control both short wavelength (Property F) and long wavelength (Property E) regularity. All points surveyed should be within 15mm from datum.

Surveying Techniques

We use a precise 3m grid of points set out across the entire floor area to ensure accuracy. Key surveying techniques include:

- Property E Measurement: Using an Engineer’s Precise Level & Parallel Plate Micrometer.

- Property F Measurement: Conducted by a third party with a digital profile meter.

iNDUS+ Edge – Concrete Technologist

Concrete quality is crucial to the success of any flooring project. Our professional concrete technologists manage the mix design and control key parameters such as:

- Workability

- Compressive strength

- Shrinkage

- Rate and timing of bleed

- Setting time

- Concrete/aggregate grading curves

- Fibre mixing

- Quality of component materials

Concrete Quality Control

To maintain high standards, we conduct regular tests, including:

- Slump Tests: At least twice a day to measure consistency and workability.

- Cube Casting and Testing: Performed at 7 and 28 days to determine compressive strength.

- Temperature Tests: Regular monitoring to ensure proper curing and performance.

Documentation and Accountability

All test results are meticulously recorded and submitted for review, ensuring transparency and accountability. This rigorous approach guarantees that our concrete floors are durable, safe, and cost-effective, meeting the specific needs of industrial and commercial spaces.

At Indus Arabia, our commitment to concrete quality control ensures that every project meets the highest standards. From initial mix design to final testing and surveying, we employ advanced techniques and stringent measures to deliver exceptional flooring solutions. Trust Indus Arabia for your next project to experience unparalleled quality and durability.

Ready to ensure your concrete flooring project meets the highest standards? Contact Indus Arabia today to learn more about our comprehensive quality control measures and how we can help with your next project.