Introduction to Concrete Floor Polishing

Concrete floor polishing has become a popular choice in the construction industry in Saudi Arabia due to its durability, low maintenance, and aesthetic appeal. Polished concrete floors are known for their smooth, mirror-like finish that not only enhances the appearance of a space but also offers a long-lasting and cost-effective flooring solution. At Indus Arabia, we specialize in providing top-quality concrete floor polishing services that meet the highest standards of excellence, making us a trusted partner for industrial, commercial, and residential projects across the kingdom.

What is Concrete Floor Polishing ?

Definition and Process

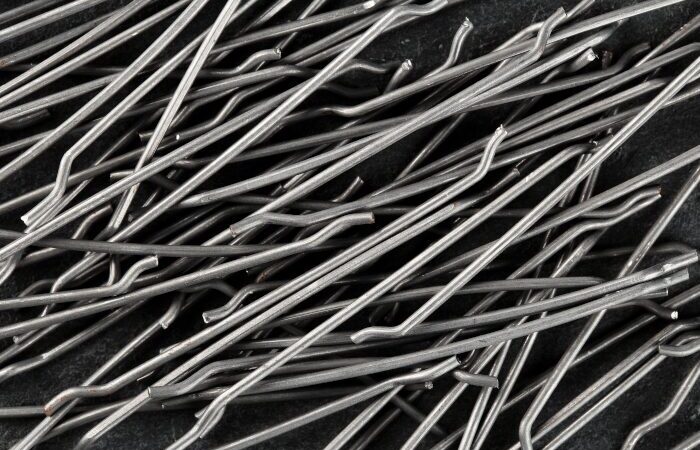

Concrete floor polishing is a multi-step process that involves grinding, honing, and polishing the concrete surface to achieve a desired level of shine and smoothness. The process begins with coarse grinding using metal-bonded diamonds, followed by finer grinding with progressively finer abrasives. The final step involves polishing the surface with resin-bonded diamonds to create a high-gloss finish.

- Grinding: The initial phase where the concrete surface is smoothed using coarse abrasives.

- Honing: Intermediate step where finer abrasives are used to refine the surface.

- Polishing: The final step that brings out the shine, creating a reflective and smooth surface.

Why Choose Concrete Floor Polishing ?

Advantages of Polished Concrete

Polished concrete floors offer several benefits that make them a preferred choice for various applications:

- Durability and Longevity: Polished concrete floors are extremely durable and can last for decades with minimal maintenance. They are resistant to heavy foot traffic, making them ideal for high-traffic areas.

- Low Maintenance: Unlike other flooring options, polished concrete requires minimal upkeep. Routine cleaning with water and a neutral cleaner is typically sufficient to maintain its shine.

- Aesthetic Appeal: The polished surface creates a sleek and modern look that enhances the overall ambiance of any space. The ability to customize the finish with different colors, patterns, and aggregate exposure adds to its versatility.

Design Flexibility and Customization – Concrete Floor Polishing

Limitless Design Choices

One of the most appealing aspects of polished concrete is the ability to customize the finish to meet specific design preferences. You can choose from a variety of colors, add aggregates or unique objects to the concrete, and control the level of light reflection by adjusting the polishing technique.

- Color Options: Practically any color can be integrated into the concrete to match the desired aesthetic.

- Aggregate Exposure: Adding aggregates such as stones or glass to the concrete mix can create a unique and eye-catching finish.

- Light Reflection Control: By varying the polishing levels, you can achieve different degrees of shine, from a matte finish to a high-gloss reflective surface.

Applications of Concrete Floor Polishing

Industrial Use

Polished concrete is particularly well-suited for industrial environments such as warehouses, factories, and distribution centers. Its durability and resistance to wear make it an ideal choice for areas with heavy machinery and constant foot traffic.

- Warehouses and Distribution Centers: The smooth, flat surface facilitates easy movement of goods and machinery.

- Factories: Provides a robust flooring solution that can withstand the demands of an industrial setting.

Commercial Use

In commercial spaces like retail outlets, showrooms, and office buildings, polished concrete enhances both functionality and aesthetics. The reflective surface can brighten up spaces, reducing the need for artificial lighting and creating an inviting environment for customers and employees.

- Retail Outlets and Showrooms: The polished finish enhances the visual appeal of products and displays.

- Office Buildings: Offers a professional and modern look that complements a wide range of interior designs.

Residential Use

Polished concrete is also gaining popularity in residential settings, offering a stylish and practical flooring solution for homes. Its modern appearance and low maintenance requirements make it an attractive option for kitchens, living rooms, and basements.

- Residential Homes: Polished concrete floors are ideal for creating a contemporary, seamless look in living spaces.

Maintenance and Longevity

Ease of Maintenance

Polished concrete floors are known for their ease of maintenance. Unlike other flooring materials, polished concrete does not require waxing, sealers, or frequent refinishing. Routine cleaning is simple, requiring only water and a neutral pH cleaner to keep the surface looking new.

- Long-Lasting Performance: With proper care, polished concrete floors can last for more than 20 years, making them a cost-effective flooring solution for both residential and commercial properties.

Indus Arabia’s Expertise in Concrete Floor Polishing

Experience and Certification

At Indus Arabia, we pride ourselves on delivering high-quality concrete floor polishing services across Saudi Arabia. Our team of skilled professionals is equipped with the latest techniques and equipment to ensure that every project meets the highest standards of excellence. We are certified and experienced in all aspects of concrete polishing, ensuring that our clients receive the best possible results.

Advanced Technology and Equipment

We use state-of-the-art polishing machines, including planetary machines with 3/4 heads, to achieve the perfect finish on every project. Our equipment allows us to create a consistent, high-gloss finish that enhances the beauty and durability of concrete floors.

Case Studies: Successful Projects in Saudi Arabia

Indus Arabia has successfully completed numerous concrete polishing projects across Saudi Arabia. Our work has been featured in various industrial, commercial, and residential settings, showcasing the versatility and quality of polished concrete floors. Clients have consistently praised our attention to detail, professionalism, and ability to deliver exceptional results on time and within budget.

Process and Implementation

5-Step Concrete Polishing Process

Our concrete polishing process involves five key steps to achieve the desired level of shine and smoothness:

- Initial Grinding: Coarse grinding to remove imperfections and prepare the surface.

- Intermediate Grinding: Refining the surface with finer abrasives.

- Honing: Smoothing the surface to eliminate scratches and marks.

- Polishing: Achieving the final shine with resin-bonded diamond abrasives.

- Final Finishing: Applying a sealer or densifier to enhance the durability and appearance of the floor.

Cost and Time Efficiency of Concrete Floor Polishing

Cost-Effective Flooring Solution

Polished concrete offers a cost-effective flooring solution for large-scale projects. The long lifespan and minimal maintenance requirements reduce the overall cost of ownership, making it an attractive option for both commercial and residential applications.

Quick Turnaround

Indus Arabia’s efficient processes and advanced equipment allow us to complete concrete polishing projects quickly and with minimal disruption. Our team works diligently to ensure that each project is completed on time, allowing clients to enjoy their polished concrete floors without delay.

Conclusion: Why Concrete Floor Polishing is the Best Choice for Your Project

Concrete floor polishing by Indus Arabia is the ultimate solution for achieving a durable, low-maintenance, and visually stunning floor. Whether you’re looking to enhance the appearance of a warehouse, retail space, or residential property, our polished concrete floors offer the perfect combination of aesthetics and functionality.

Ready to elevate your space with polished concrete floors? Contact Indus Arabia today to learn more about our concrete floor polishing services in Saudi Arabia. Contact US for more information and to request a consultation.